PAHWA METALTECH P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PAHWA METALTECH P LTD.

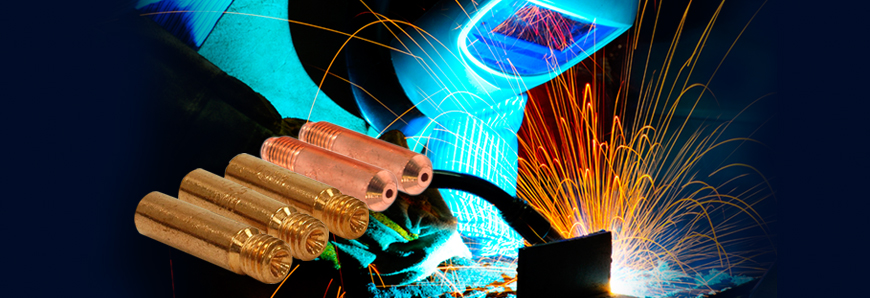

Resistance Welding Products

Copper Alloys find its very common application in resistance welding equipment and tools.

Selecting the right copper alloy for resistance welding equipment particularly for gun arms, Projection welding electrodes, Seam welding wheels and Spot welding electrodes and caps is dependent on large number of design criteria and most often it is a trade-off between strength and electrical conductivity.

Copper Chromium and Copper Chromium Zirconium alloys have good thermal conductivity but tend to soften at lower temperatures thereby by significantly reducing the quality of weld and life of electrode. Copper Beryllium (RWMA Class 3 and 4) alloys are used high weld force or high weld currents are required. However these alloys are expensive for commercial applications and therefore are ususally substituted with less expensive materials.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.